Evercloak’s invisible film could help fight COVID

With funding from Canada’s Department of National Defence (DND), Evercloak is leveraging its revolutionary nanomaterials to give frontline workers a powerful new layer of protection.

In 2020, DND issued a challenge through its Innovation for Defence Excellence and Security (IDEaS) program: find ways to allow frontline workers to reuse gloves, gowns, face shields and other personal protective equipment (PPE). Evercloak responded with a bold plan to apply its advanced nano-films, securing $147,000 in funding.

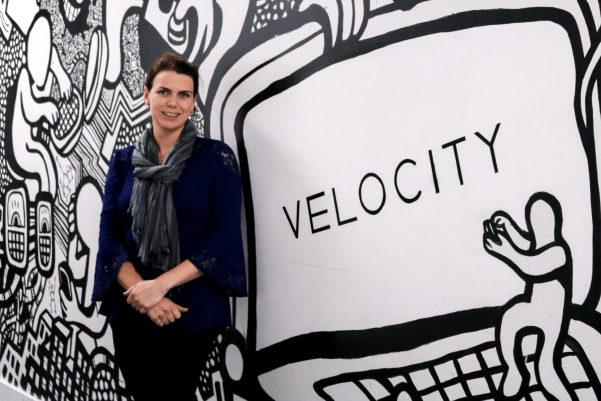

“Evercloak is commercializing ultra-thin nanofilms to radically improve energy efficiency in air conditioning systems,” says Evelyn Allen, CEO of the Waterloo start-up. “But we know that nanomaterials have a huge number of applications. So when the pandemic hit, we looked at how our technology could help fight COVID-19 and other infectious diseases.”

Evercloak’s team, in partnership with researchers from the University of Waterloo, is engineering a germ-fighting film that can be applied to PPE to inactivate coronaviruses and other disease-causing microbes. Now, funding from IDEaS will enable Evercloak to work with Dr. Pope’s lab at the University of Waterloo to advance this radical new technology.

When the coating is exposed to indoor lighting — including light from standard LED and fluorescent bulbs — it produces reactive species that kill viruses and microorganisms. As long that light continues to shine, the coating keeps pumping out those reactive species, providing ongoing protection without the need to wipe down surfaces with ethanol or other antimicrobial cleaning products.

Because the film is transparent, it is ideally suited for face shields, goggles and protective barriers, but it can also be applied to opaque materials such as gloves, gowns, masks and uniforms.

Being one step closer to bringing this anti-viral solution to market means that we will soon be better able to protect first responders, healthcare workers and military personnel dealing with biological hazards, keeping their gear continuously disinfected. And it will kill viruses before they’re transferred to other surfaces, patients or colleagues.

“Although the coatings are too thin to see, they’re incredibly powerful,” says Allen. “This project is enabling Evercloak to validate their efficiency not only against COVID-19, but it may also be applicable against a wide range of viruses.”

That’s not the only benefit. This technology also means PPE can be reused instead of thrown away at the end of a shift — reducing significant waste, saving money and making healthcare facilities and military missions less vulnerable to supply shortages. Ultimately, this technology could be applied in a whole range of settings, from ambulances to grocery checkouts.

“We’re proud to be developing solutions that will keep frontline workers safe,” says Allen. “We’re also proud to be positioning Canada as a leader in advanced materials and nanotechnology.”

She notes that developing these coatings will create new jobs and manufacturing opportunities as they move from the lab into commercial production.

“Nanomaterials are incredibly versatile and have the potential to address all sorts of pressing health and environmental challenges,” Allen says. “With support from Government of Canada’s IDEaS, we’re turning that potential into reality.”